description

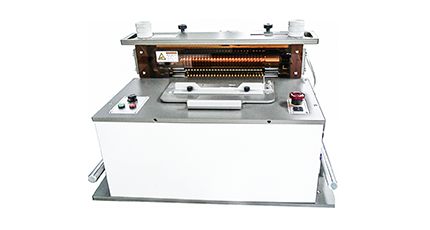

Rotary Slitter is a robust cutting instrument which is designed to slit a wide range of rapid test materials, typically of finished cards/uncut sheets/glucose rows into final strip forms. This powerful unit equipped with rotary blade type features an ultra-fast cutting operation that yields high throughput as well as production efficiency.

The simple yet highly efficient unit works by manually loading the card into the blades (card length and strip width determines blade count) for a swift slitting action. At less than a second, the cut strips are discharged onto a collection tray or down the chute (optional) for quick and convenient collection into a bottle. The blade head can be easily removed and *swapped for cutting different width size.

(*Does not apply to RCG-100)

Quality & Performance

- Increased productivity: Entire card is cut into strips instantly in one pass.

- Solid construction with top quality components for durability.

- Specially developed blade types for optimized cutting of different materials.

- Specially coated blades for improved lifespan.

- Built-in anti-static Ionizer reduces strip sticking issue due to static cling.

Ease of Use

- Simple operation and low maintenance provides for hassle-free usage.

- Easy removal of blade head for different cutting requirement

(*RCG-100 excluded).

- Convenient QC access: As the cut strips are uniformly spread out on the collection tray, defects in strips (improper dispense coating, gluing, length, etc.) can easily be identified for removal.

- Collection chute for quick and convenient strip bottling.

- Additional blade head for cutting more than one strip size. (e.g. 3, 4, 5 mm, etc.)

(*RCG-100 excluded)

- RCI-310 has been specially developed to handle specific type of cards that have pre-printed backing where each of the strip on card is marked.

The Auto-alignment feature (motor-driven) automatically positions the loaded card as per the print markings and then feeds the card for precise cutting of each strip in between the printings.

MODELVODAPPLICATIONMATERIAL/PROCESS MORE INFO

-

RCI-300

IMMUNO Card / Uncut Sheet > Test Stripsmore info

IMMUNO Card / Uncut Sheet > Test Stripsmore info

1.jpg)

SPECIFICATIONS: RCI-300

- - Card Feeding Method

- : Manual

- - Capacity

- : 720 cards/hour (Based on 5 second card feeding interval)

- - Applicable Card Length

- : Max. 320 mm

- - Applicable Card Width

- : Max. 100 mm

- - Applicable Card Thickness

- : Max. 2.5 mm (Depends on the characteristics of card)

- - Strip Cut Width

- : (Cut size is made to order)

- - Cutting Accuracy Tolerance

- : Less than 0.1 mm

- - Dimension

- : (Approx.) 682(L) × 430(W) × 370(H) mm

- - Weight

- : (Approx.) 86 kg

- - Power

- : 110 or 230 V, 50 or 60 Hz

- - Current

- : 0.4 KVA, 3 A

SPECIFICATIONS: RCI-310 (Auto-align feature for printed cards)

- - Card Feeding Method

- : Automatic (motor-driven)

- - Capacity

- : 420 cards/hour (Based on 8 second card feeding interval)

- - Required Card Marking Size

- : More than 0.5mm

- - Edge Sensor

- : Photo sensor or color sensor(Depends on type of card markings)

- - Applicable Card Length

- : Max. 320 mm

- - Applicable Card Width

- : Max. 100 mm

- - Applicable Card Thickness

- : Max. 2.5 mm (Depends on the characteristics of card)

- - Strip Cut Width

- : (Cut size is made to order)

- - Cutting Accuracy Tolerance

- : Less than 0.1 mm

- - Dimension and Weight

- : NA (Available upon request)

-

RCU-200URINECard / Uncut Sheet > Dip Sticksmore info

SPECIFICATIONS

- - Card Loading Method

- : Manual

- - Capacity

- : 720 cards/hour (Based on 5 second card feeding interval)

- - Applicable Card Length

- : Max. 256 mm

- - Applicable Card Width

- : Max. 135 mm

- - Applicable Card Thickness

- : Max. 2.5 mm (Depends on the characteristics of card)

- - Cutting Accuracy Tolerance

- : Less than 0.1 mm

- - Cut Width (strips)

- : 5 mm (Or as per customer’s requirement)

- - Dimension

- : (Approx.) 682(L) × 410(W) × 365(H) mm

- - Weight

- : (Approx.) 86 kg

- - Power

- : 110 or 220VAC, 1P, 50/60Hz

- - Current

- : 0.8KVA, 7A

-

RCG-100GLUCOSEUncut Row > Cell Stripsmore info

SPECIFICATIONS

- - Row Feeding Method

- : Manual

- - Capacity

- : 720 rows/hour (Based on 5 second feeding interval)

- - Row Length

- : Max. 280 mm

- - Row Width

- : Min. 25 mm

- - Cut Width (strips)

- : (As per customer’s requirement)

- - Dimension

- : (Configuration dependent) 700(L) × 500(W) × 450(H) mm

- - Weight

- : (Configuration dependent) 100 kg

- - Power

- : 110 or 220VAC, 1P, 50/60Hz

- - Current

- : 0.5KVA, 5A

1.jpg)